3-D scanning

CAD/CAM softwares to accurately machine the tooling.

Testing of non-dimensional attributes of samples for a better understanding of the materials involved and the functional parameters of the products.

11238 different Tools & Dies.

VMC Machines

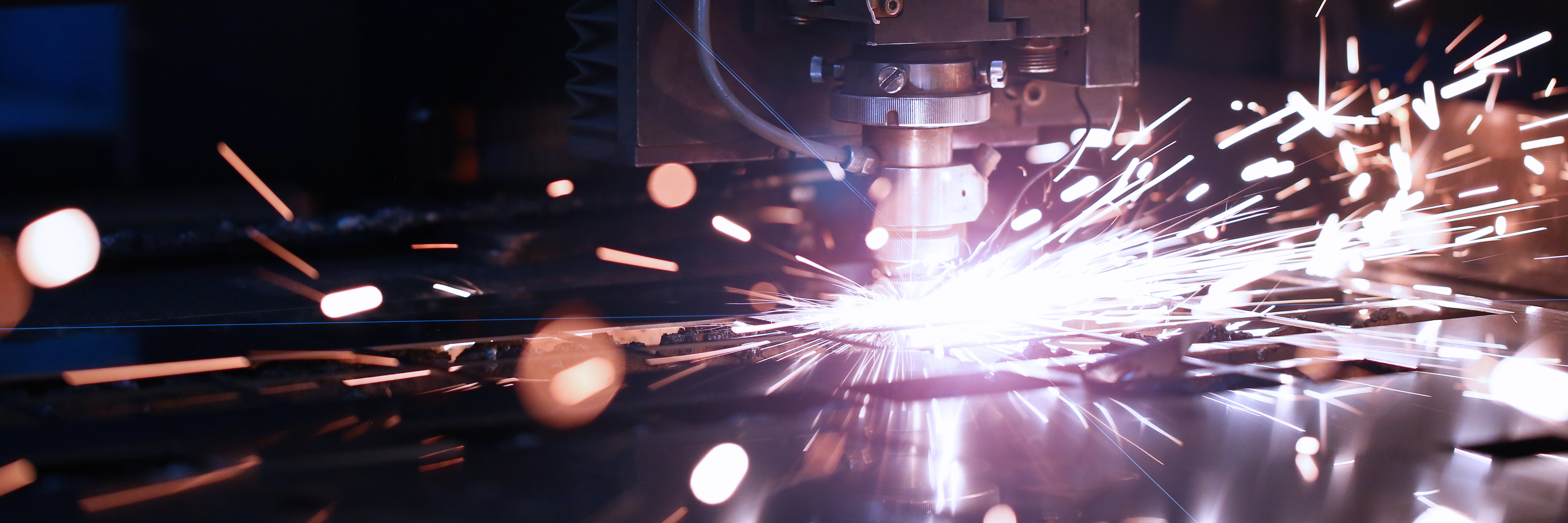

CNC Wire Cutting Machines

CNC Milling Machine

Pantograph Machines

Drilling Machines

CNC Machining Centers

CNC Lathe Machines

Electronic Spark Erosion Machines (EDP)

Centerless, Cylindrical 6 Surface Grinders

Digitally Controlled, CNC and 3 Quadrant Measuring Machine

Robotic SPN For Critical Operations

Lathe Machines - Manual, Semi-Automatic, Turret

Boring Machines

Broaching Machines

Induction Hardening Furnaces

Shaping & Planning Machines

Milling Machines

Grinders - Centreless, Cylindrical, Surface

Welding Machines— MIG, ARC & SPOT

120+ mechanical and hydraulic sheet metal presses

Capacity to process upto 1000 tons of steel each month

Deep drawing execution capacity upto 200 mm in depth

Equipped with computerised shearing machines

Mechanical power presses ranging from 60 - 350T and Double action hydraulic power presses of 150 -300T

Automotive grade fasteners as per DIN, JIS, SAE and BS are welded as per defined automotive standards to stampings to achieve the required torque strength

Robotic welding machines for critical high accuracy sheet metal components

Supervised by qualified rubber technologists using fully integrated laboratory.

200 tons of tailor made rubber compounds processed each month as per customer and product requirement.

Tested to obtain desired pre-moulding, ageing, durability and physical curing characteristics, tensile strength, elongation, hardness, ageing and durability.

Correct grade polymers and chemicals are used to match intended use.

Scientifically inventoried mixes are kept in air conditioned, environment-controlled chambers.

The entire process is monitored batch wise.

Rubber produced is tested on equipments such as Rheometer, Mooney Viscometer, Dynamic & Static Testing Machines, Ultrasonic Testing and Hardness Testing equipments etc. to ensure meeting of customer and field requirements.

Largest infrastructure in Asia dedicated solely to aftermarket operations.

Producing nearly 800,000 general moulded rubber parts every month.

More than 115 sophisticated PLC controlled machines of German, Korean and Taiwanese origins for Injection Moulding, Compression & Transfer Moulding and Cold Runner technology.

Automated phosphating plant with programmable transporter.

Automatic degreasing machines.

Shot & sand blasting machines for pre-moulding and final finish to the metal surface.

Ability to do various finishes including E-Coating and PU Coating.

Control over the range of coat thickness, in microns, to meet different salt spray standards.

Strict Process Control mechanism is built in the machine to control the required quality of paint surface finish.