Vibration control products like Engine & Transmission Mount are critical to a vehicle as they bear the engine weight and also supports the torque generated during the movement of the vehicle. Sigma’s vibration control products are designed to match OE standards of fit, function, performance, and materials (natural rubber, high tensile steel, aluminum die cast and polymers) to deliver the desired static and dynamic loads, isolate engine noise and dampen engine vibrations in extreme weather conditions. They are superior in design to ensure comfort from mass forces during acceleration and deceleration of the vehicle.

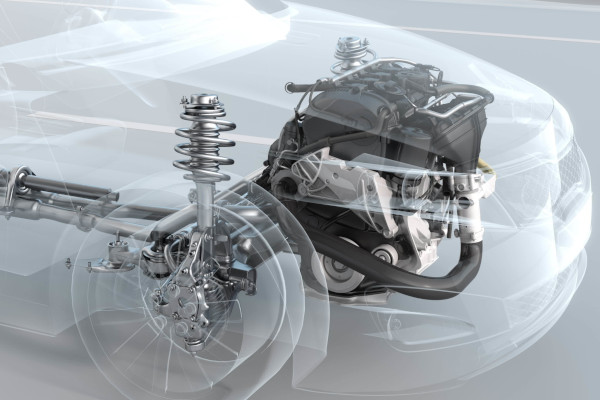

Suspension systems plays a key role in road holding/handling and ride quality as the vehicle cruises down the road. The suspension system’s primarily role is to ensure that the vehicle remains insulated from the shocks encountered due to the tire-road contact forces and to maximize the overall performance of a vehicle whilst maintaining a safe and comfortable ride. The suspension systems manufactured by Sigma are reversed engineered to strictly match the OEM design and specifications for the global aftermarket segment.

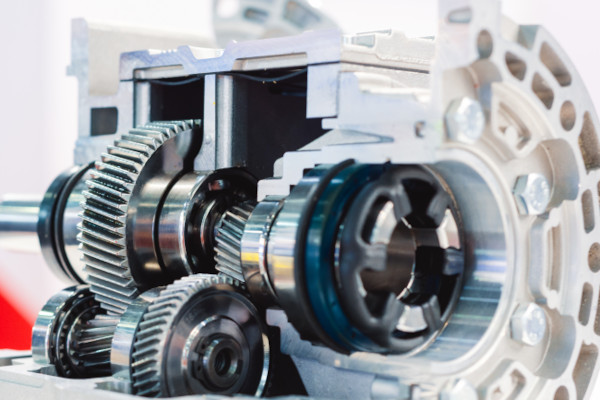

A Drivetrain is the group of components of a vehicle that work together with the engine to deliver power to wheels and different parts of the vehicle to drive the vehicle into motion. The engine generates energy to power a flywheel which in turn works with the transmission and regulates the amount of power delivered to the other components of the drivetrain. The driveshaft then spins and powers the differential which in turn distributes the power to the wheels thus propelling the vehicle into motion.

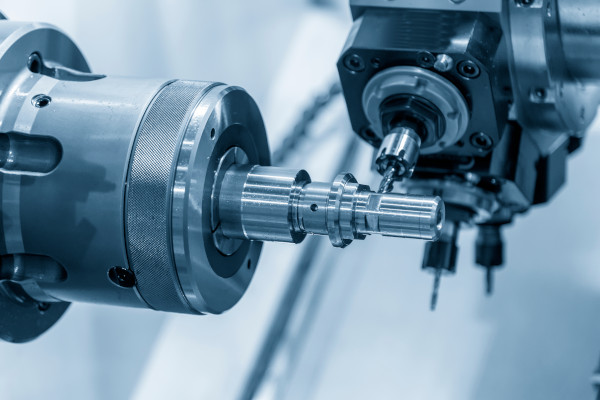

Precision Machining can be defined as utilizing the highest function of a tool, program, engineering talent or equipment thus pushing the limits of design feature creation and materials science under the tightest tolerances defined by any sub-set of these manufacturing parameters. It is a type of technical manufacturing that is essential in creating and designing machines, parts, tools, and other hardware that are essential in modern manufacturing to maintain process controls and tolerances that function under extremely tight specifications. Sigma’s advanced manufacturing processes coupled with its technological engineering expertise and quality systems has enabled it to successfully supply various high precision machined parts in India as well as to export markets for over a decade now.

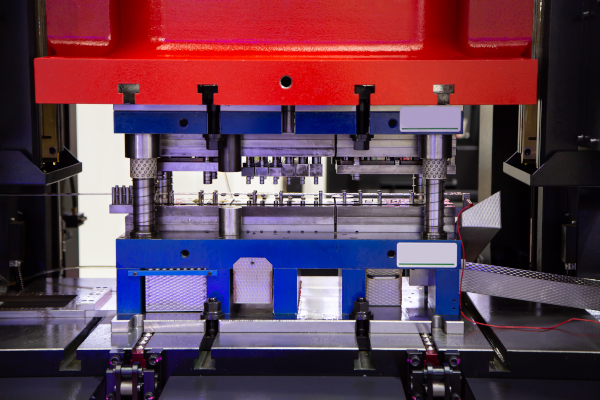

Stamping (also known as pressing) is the manufacturing process to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metals forming techniques — punching, blanking, bending, coining, embossing, and flanging. More specifically it involves placing a flat sheet metal in either coil or blank form into a stamping press. In the press a tool and die surface form the metal into the desired shape. Sigma’s state of the art presses with cutting edge technology has enabled it to offer wide ranging product variety for sheet metal related assignments coupled with high performance, quality and cost competitiveness.